What should be paid attention to in the daily inspection and maintenance of the bulldozer?

To make inspection and maintenance of bulldozers,we need to follow the steps below:

Bulldozers product processing requirement is high, the difficulty is big, once appear in the process of the bulldozers used outdoors unexpectedly fault, then lost miserably.

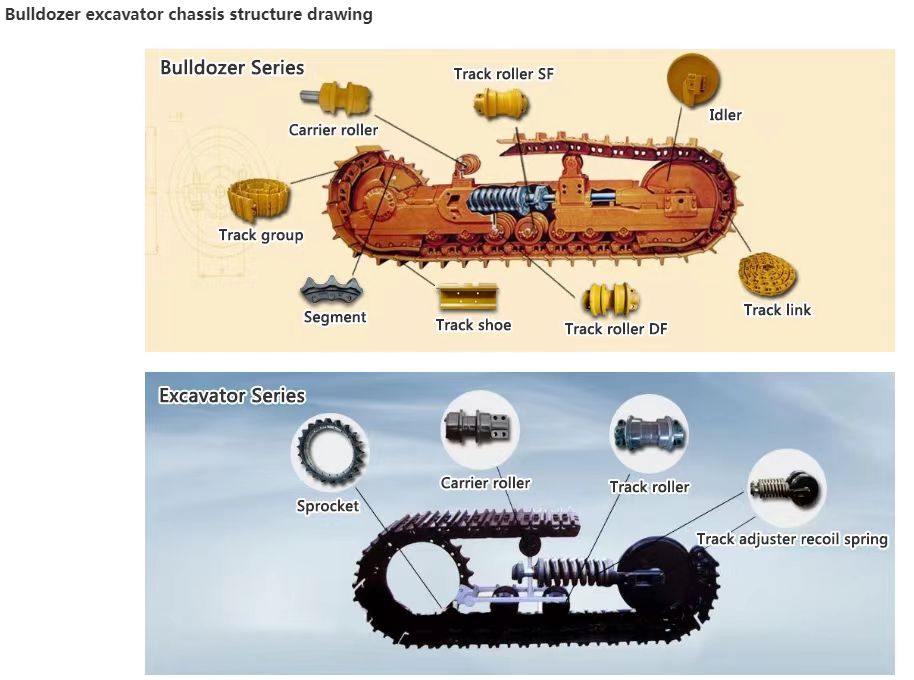

Before you start the engine, check the machine around and under the machine, check whether loose nuts and bolts, with and without oil, fuel and coolant leakage, and inspect the condition of the working device and hydraulic pressure system, also check any loose wires, with or without clearance, and in the high temperature parts of the presence of dust accumulation; Inspection device, cylinder, connecting rod, tube crack, excessive wear or clearance. If discovery is unusual, and should be repaired. Check accumulate around the engine and radiator dirt or dust, check the battery or high temperature engine parts (such as engine muffler or turbocharger) around the accumulation of flammable materials (dry leaves, branches, grass, etc.), remove the dirt and flammable.

High pressure pipe joint and oil cylinder, floating oil seal, radiator fin, the pipe joint leakage, if any should be ruled out in time. Electrical system with and without broken wires, short-term, terminal is loose, if any should be ruled out in time. Engine oil sump oil check: in the state of engine downtime, should first determine if the engine oil pressure gauge, thermometer is in the normal range, and then remove the oil dipstick check the fluid level should be between the oil dipstick upper and lower scale line. If you need to add oil, open the mouth filling in. Check the oil level, the vehicles should be parked on a level surface. Add oil, oil level not higher than "H" tag.

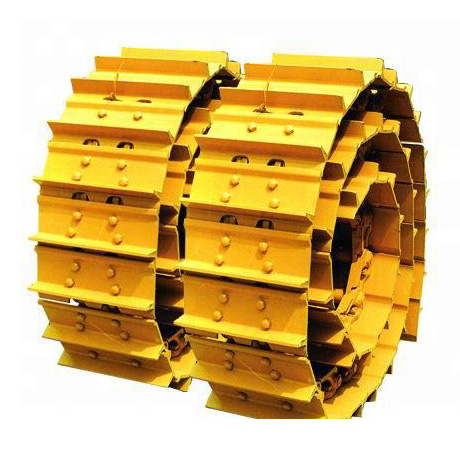

Crawler tensioning degree of adjustment, it is by giving the tensioning cylinder injection nozzle butter or from the drain out of butter, with reference to the standard clearance adjusted model. When tracked successively from stretched to a group need to remove the track section, the drive tooth surface and pin set of mating surface may also be influenced by wear and tear, at this time should be dealt with properly before meshing deterioration, such as pin and pin sets, replacement of worn excessive pin and pin set, change the track section assembly, etc.

Running gear lubrication is very important, a lot of roller bearing caused by "burned" subscription fee is not found in time because of the oil spill. Generally believe that the following five possible leak: due to the baffle ring and shaft between the o-ring bad or damaged, the baffle ring between the lateral and axial leakage; Because of floating seal ring is poor contact or o-ring defects, from lateral baffle ring and roller (roller, guide wheel, driving wheel) between the oil; Because of the roller (roller, guide wheel, driving wheel) between the bushing and the o-ring, oil between sleeve and roller; Refueling because of screw loosening or tapered plug seal hole damage, oil plug in oil; Because of the bad o-ring, oil between block cover and roller. Therefore, at ordinary times should pay attention to check the above parts, and according to the different parts of the lubrication cycle to add, change regularly.