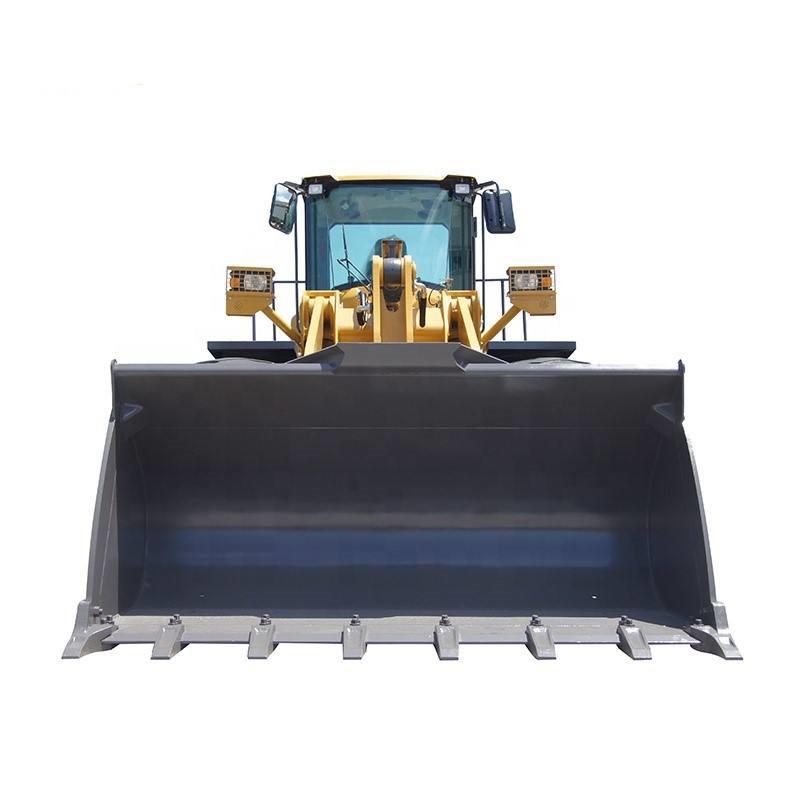

How to make maintenance and care of the undercarriage for construction machinery summer?

Maintenance and care of the undercarriage for construction machinery in summer:

In the hot summer, do a good job of the construction machinery heat prevention work becomes the main event in the mind of the owners, how to let the love machinary spend the summer in good state? Today we introduce the summer chassis assembly or system maintenance and maintenance, hope we can help you.

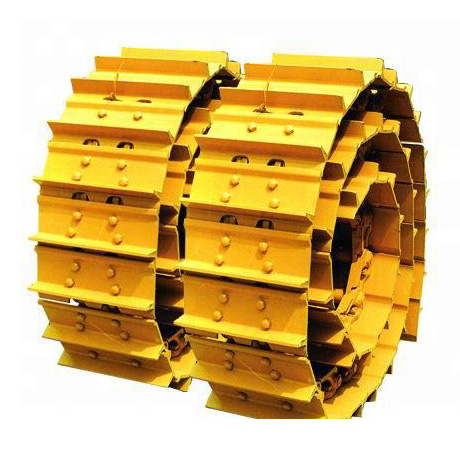

Chassis assembly parts

Release the lubricating oil of each assembly of the chassis, after cleaning the reducer, main reducer, side reducer and steering gear Huanong thick summer gear oil, wheel bearing change to the lubricating oil with higher drop point.

Hydraulic system section

Release the original hydraulic oil of the hydraulic system, replace the hydraulic oil in summer. In addition to cold areas such as Northeast China, North China and Northwest China, No. 40 low temperature hydraulic oil can continue to be used. Hot areas such as Jiangnan should be replaced with N68 anti-wear hydraulic oil, and general areas should be replaced with N68 ordinary hydraulic oil. At the same time, due to the hot and rainy summer, but also especially to prevent water or air into the hydraulic system. Because the water or air into the hydraulic system, the oil pump will be transformed into high pressure oil, air and water will promote the increase of heat in the system and cause overheating, overheating will make the oil dilute, and accelerate the oxidation of the oil, and accelerate the wear and corrosion of the parts in the system, reduce the transmission efficiency of the system.

Hydraulic system braking engineering machinery

For construction machinery with hydraulic braking system, check the brake master pump and sub-pump, replace the brake oil with a high boiling point (not less than 115-120), thoroughly exhaust the air in the brake pipe, and check and adjust the height of the brake pedal. For pneumatic braking construction machinery, pay attention to check the brake bowl and brake hose, found damage should be replaced in time.

Tire part

When construction machinery works under high temperature conditions, the speed of tire heat dissipation is slow, and the pressure is correspondingly increased, which is easy to cause tire blasting. When working under high temperature conditions, the temperature and air pressure of the tire should be checked frequently to ensure the stipulated air pressure standards. If the tire is found to be short of air, it should be made up in time, never make do with work. Mechanical stop, should try to stop in the shade, tire temperature is found to be too high, do not use cold water method to reduce the temperature of the tire, this will be due to the tread and the side of the rubber layer of each part of the uneven contraction crack.